Can you impress today’s customers with an 80-year-old technology? This is what the trinamiX development team achieved with the infrared sensor Hertzstück™.

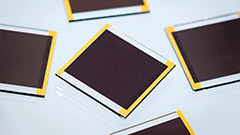

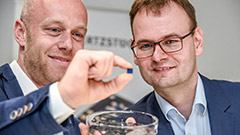

„We cannot fulfill your product requirements.” This was the response of all suppliers when trinamiX wanted to order certain sensors in the form of a small chip and in high numbers. A disappointing message. To manufacture an optical sensor system for distance measurement, the team working with Dr. Sebastian Valouch and Dr. Wilfried Hermes were searching for something not yet existing in this form: a wafer-thin infrared sensor made of lead salt. The models previously available on the market were very sensitive to water and oxygen, which is why they are protected by a sort of tin can: five millimeters thick – a true waste of space in the miniaturized world of microchips.

At this point the story could have already ended. However, the will and pragmatism of the BASF subsidiary persisted. Working in a team, they pooled electronics knowledge and chemical expertise and, in April 2015, they started developing their own sensor with ultrathin encapsulation.

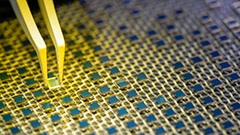

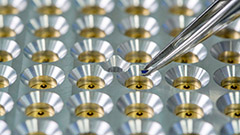

From the start, chemical and process development closely coordinated their activities, and only those ideas were implemented that would also work in series production. At the beginning, there was considerable discussion in the team – about 20 process steps had to be coordinated with one another. But, ultimately, the production could be moved almost directly from the lab to mass production.

Equipped with product samples and data sheets, the team talked to potential customers and presented the 0.5-millimeter-thick chip with thin-film encapsulation to experts – and sold the first Hertzstück™ already one month later.

We developed the sensor in only 18 months and established our own production. And the properties of our sensors were so good that we wanted to offer them to external customers as well.

Hertzstück? The name is telling

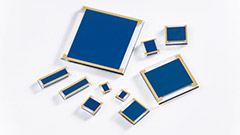

The sensor is the heart of every measurement device. The less light needed to obtain good results, the higher the performance, the so-called “detectivity”. In their formula, the unit “root-Hertz” plays a particular role. This is where the “tz” in the brand name and the root in the product logo stem from. The Hertzstück™ sensors come to life in the in-house production in Ludwigshafen. From the chemical deposition to the encapsulation – trinamiX produces the sensor in the chemical lab and clean room in mass production according to the intended use and in different sizes.

The special potential offered by the inexpensive and high-performance sensors can be found in applications involving miniaturized electrical engineering: Without the oversized casing, the chip could be integrated in corresponding measurement devices in smartphones – and in the future enable consumers to scan food for contamination as well as for water and sugar content. Many more measurements and applications are conceivable.